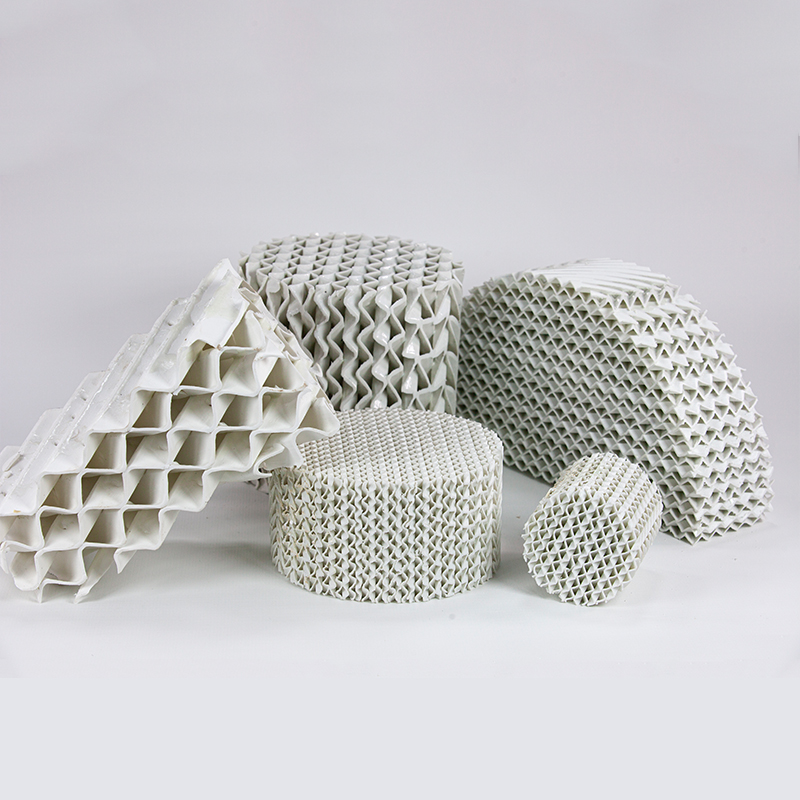

Factory Heat resistance Combined Cermaic Light Packing for scrubber Tower

| Boholo | X-01 | X-11 | X-12 | X-13 | X-14 |

| Bophara ba ka ntle(mm) | 220±25 | 220±25 | 220±25 | 220±25 | 220±25 |

| Sebaka(mm) | 20 | 20 | 20 | 20 | 20 |

| Boholo ba pore(mm) | 65 | 65 | 65 | 65 | 65 |

| Sebaka se ka holimo(m2/m3) | 118 | 128 | 135 | 132 | 148 |

| Bolumo ea mahala(%) | 85 | 75 | 72 | 75 | 73 |

| Boima ba Bongata(kg/m3) | 280 | 320 | 340 | 300 | 348 |

Melemo ea ho sebelisa liphutheloana tse bobebe tsa ceramic ke tse latelang:

1. Sehlahisoa se na le li-micropores tse tsoetseng pele hantle le bokhoni bo matla ba ho khomarela le ho bapatsa litšila; Ho kenella ha khase e phahameng, li-micropores tse ntlafalitsoeng hantle, le matla a matle. E tšoarella ho ts'oaroa, tšusumetso, le phallo ea moea. Porosity ea eona e hlakileng ke ≥ 15%, 'me e na le matla a ho khomarela le adsorption bakeng sa litšila tse fapa-fapaneng tsa khase, metsi le mekhoa e meng ea ts'ebetso, e nang le phello e ntle ea tlhoekiso.

2. Boima ba sehlahisoa se bobebe, matla a phahameng a mochine, le ho hanyetsa ho tlaase

Boima ba ho bokella lihlahisoa tse bobebe tsa ceramic filler ke 280-350kg/m3, e tlase haholo ho feta boima ba li-stacking tsa li-filler tse tloaelehileng tse tloaelehileng. The stacking porosity ea sehlahisoa ke ≥ 72%, porosity e bonahalang ke ≥ 15%, 'me kakaretso ea porosity e feta 85%. Mask e na le melemo ea boima bo bobebe, mojaro o monyane, ho hanyetsa ts'ebetso e tlase, le khatello e fokotsehileng ea tora e tletse.

Joalo ka sephutheloana se hlophisitsoeng, sehlahisoa se na le khanyetso e omeletseng ea tora ea metsi a ka tlase ho 50mm le khanyetso ea ts'ebetso ea metsi a ka tlase ho 100mm ka tora ea ho hlatsoa ea naphthalene e nang le phallo ea khase ea 50000 m3 / hora, e etsang hore e se ke ea thijoa habonolo le ho hlola mefokolo ea ho phatloha habonolo le ho koaloa ha li-fillers tse hlephileng.

3. Coefficient e phahameng ea ho fetisa boima, sebaka se seholo se sebetsang, le phello e ntle ea karohano

Tekanyo ea ts'ebetso ea li-filler tsa ceramic tse bobebe ke Univesithi ea Tianjin e bonts'a hore sehlahisoa se na le coefficient e phahameng ea phetisetso ea boima, e leng makhetlo a 2,2 ho feta a li-filler tse ling. Ho phaella moo, ka mor'a hore leseli la ceramic le tlatsitsoe, ke maoto a 6 feela a tšehetso a haufi a kopanang ho etsa sebaka se sa sebetseng, 'me phetisetso ea khase ea mokelikeli ke mokhoa oa ho kopana le "ka holim'a metsi". Ntle le moo, leseli la ceramic filler ke ceramic e nang le khekhe ea linotsi e nyane e nang le sebaka sa microporous le sebaka sa marotholi a sebaka, se etsang hore sebaka se sebetsang sa ho tlatsa se be seholo ho feta 99.5%, se hlahisang litlamorao tsa karohano le tlhoekiso.

4. Li-filler tsa ceramic tse bobebe li na le khanyetso e matla ea botsofali, ho hanyetsa kutu, le bophelo bo bolelele ba ts'ebeletso

Mochine o khanyang oa ceramic o na le mocheso o motle oa ho hanyetsa mocheso, o hanyetsanang le mollo ho fihlela ho 1400 ℃, 'me o hanyetsa ho pholile ka potlako le ho futhumatsa; Holim'a moo, li-filler tse tloaelehileng tsa likoti tse supileng tsa ceramic li na le acid e ntle haholo le khanyetso ea alkali, bophelo bo bolelele ba ts'ebeletso, 'me ha e rate botsofali.

5. Lisebelisoa tsohle tsa ceramic li na le mohaho oa libuka, o ka khaoloa, 'me o bonolo ho o tlatsa

Letoto la li-filler tsa ceramic tse tloaelehileng li ka khaoloa le ho bokelloa ka har'a selikalikoe, se seng se loketseng ho tlatsoa feela, empa hape se lumella sefofane sohle sa ho tlatsa hore se sebelisoe. Li-filler tse ling tse tloaelehileng, ka lebaka la tlhaho ea tsona ea ho se itšehe, ha ho pelaelo hore li na le likheo tsa boholo bo sa tšoaneng ho pota-pota tora, e leng se bakang liketsahalo tse matla tsa lebota le groove flow, tse ka amang katleho ea tšebeliso ho ea ka maemo a sa tšoaneng.

Ka kakaretso, ho paka ka ceramic e khanyang ho rarollotse ka katleho ho hanyetsana pakeng tsa porosity le sebaka se itseng sa holim'a metsi, seo ho seng bonolo ho thibela tora empa hape se na le ts'ebetso e ntle, e leng se etsang hore e be khetho ea basebelisi ba tora ea filler.