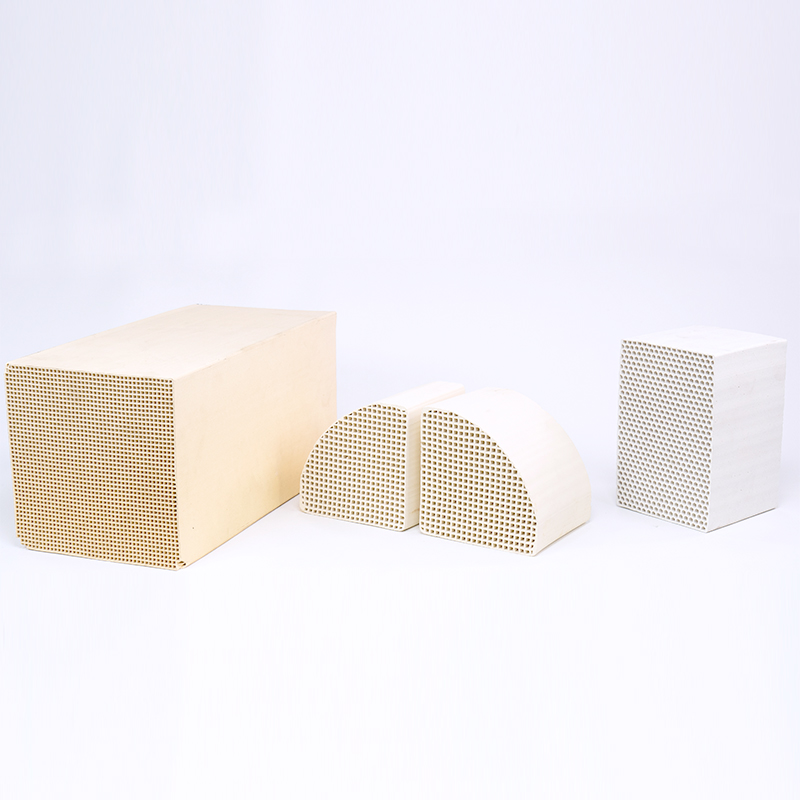

RTO - Heat Exchange Honeycomb Ceramic

Mesebetsi

1.Reduce tahlehelo ea mocheso oa khase ea ho qeta, le ho ntlafatsa bokhoni ba mafura ho boloka matla joaloka.

2. Ntlafatsa mocheso o tukang o ipapisitse le khopolo, ntlafatsa ho chesa ha sepakapaka, ho kopana le mocheso o phahameng oa lisebelisoa tse futhumatsang, eketsa mafura a nang le khalori e tlase, haholo-holo mefuta e mengata ea lisebelisoa tsa ho phatloha, ho ntlafatsa ts'ebetso ea mafura a calorific le ho fokotsa mesi e tsoang ho khalori e tlase. boleng ba khase ea mashala.

3. Ntlafatsa lipehelo tsa phapanyetsano ea mocheso libakeng tsa mollo, ho eketsa tlhahiso ea lisebelisoa, ho ntlafatsa boleng ba lihlahisoa le ho fokotsa ho tsetela hape thepa.

4.Ho fokotsa ho tsoa ha mocheso oa thepa ea mocheso, ho fokotsa tšilafalo ea moea le ho ntlafatsa tikoloho.

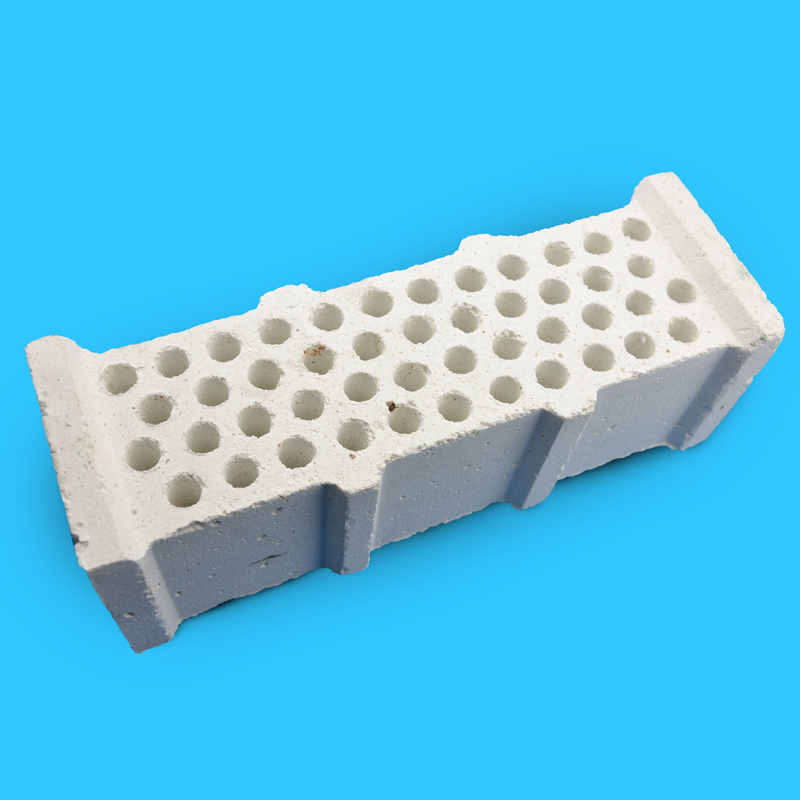

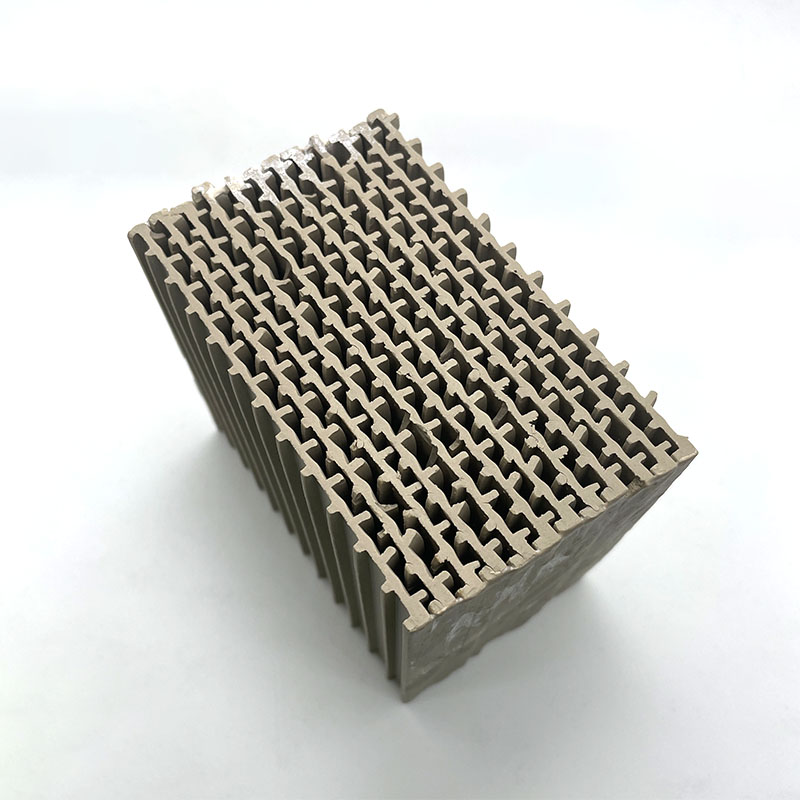

Litšobotsi

Litšobotsi tsa regenerator ea ceramic ea mahe a linotsi ke tse latelang: li na le katoloso e tlase ea mocheso, matla a phahameng a mocheso a phahameng, sebaka se phahameng se ikhethileng, ho theoha ha khatello e tlase, ho hanyetsa mocheso o tlase, ho sebetsa hantle ha mocheso, ho hanyetsa mocheso oa mocheso le tse ling tse ngata.Kahoo, indastering ea metallurgy le ea lik'hemik'hale, e sebelisoa e le HTAC, ha re ntse re kopanya ho tsosolosa mocheso oa likhase, ho chesa ka mokhoa o phahameng ka ho fokotsa NOx.E fetoha sesebelisoa sa 'nete sa ho boloka matla mme e fokotsa Nox.

Lisebelisoa: Alumina, Alumina e teteaneng, Cordierite, Dense Cordierite, Mullite, Corundum Mullite le tse ling

Kopo

Ceramic ea mahe a linotši ke senotlolo le karolo ea mantlha ea polokelo ea mocheso ea mocheso o phahameng oa theknoloji ea ho chesa (HTAC technology).E 'nile ea sebelisoa haholo liipone tse fapaneng tsa ho futhumatsa tšepe, libopi tsa ho futhumatsa mocheso, libopi tsa ho futhumatsa mocheso, libopi tsa ho qhaqha, libopi tse qhibilihisang, li-ladle/tundish roasters, libopi tse kolobisang, licheso tse khanyang, le libono tsa mofuta oa tšepe indastering ea metjhini ea tšepe.Sebopi, sebopi se phatlohileng sebopi sa moea o chesang;libopi tse fapaneng tsa ceramic le libopi tse fapaneng tsa khalase indastering ea thepa ea moaho;libopi tse fapaneng tsa ho futhumatsa li-tubular, libopi tse qhekellang le libopi tse ling tsa indasteri indastering ea petrochemical.

Litlhaloso

100x100x100, 100x150x150, 150x150x150, 150x150x300mm le tse ling

Palo ea masoba: 25x25, 40x40, 43x43, 50x50, 60x60 le tse ling

Boemo

| Boemo (mm) | Lisele (N×N) | Tekano ea Lisele (CPSI) | Bophara ba Channel (mm) | Botenya ba lebota bo ka hare (mm) | Free Cross Section (%) |

| 150×150×300 | 20×20 | 11 | 6.00 | 1.35 | 64 |

| 150×150×300 | 25x25 | 18 | 4.90 | 1.00 | 67 |

| 150×150×300 | 32 × 32 | 33 | 3.70 | 0.90 | 63 |

| 150×150×300 | 40×40 | 46 | 3.00 | 0.70 | 64 |

| 150×150×300 | 43 × 43 | 50 | 2.80 | 0.65 | 64 |

| 150×150×300 | 50×50 | 72 | 2.40 | 0.60 | 61 |

| 150×150×300 | 59x59 | 100 | 2.10 | 0.43 | 68 |

Sebopeho sa Lik'hemik'hale

| Ntho | Cordierite | Mullite | Alumina Porcelain | Alumina Porcelain e phahameng | Corundum |

| Al2O3 | 33 | 65 | 54 | 67 | 72 |

| SiO2 | 58 | 30 | 39 | 23 | 22 |

| MgO | 7.5 | <1 | 3.3 | 1.7 | <1 |

| Ba bang | 1.5 | 14 | 3.7 | 8.3 | 5 |

Thepa ea 'Mele

| Ntho | Cordierite (Porous) | Mullite | Alumina Porcelain | Alumina Porcelain e phahameng | Corundum | |

| Boima ba 'mele(g/cm3) | 1.8 | 2.0 | 1.9 | 2.2 | 2.5 | |

| Monyo oa Metsi (%) | 23 | 18 | 20 | 13 | 12 | |

| Coefficient of Thermal Expansion(×10-6K-1) (20~800℃) | ≤3.0 | ≤6.0 | ≤6.3 | ≤6.0 | ≤8.0 | |

| Mocheso o Khethehileng (J/Kg.K) (20~1000℃) | 750-900 | 1100-1300 | 850-1100 | 1000-1300 | 1300-1400 | |

| Thermal Conductivity (W/mk) (20~1000℃) | 1.3-1.5 | 1.5-2.3 | 1.0-2.0 | 1.5-2.3 | 5-10 | |

| Max.Mocheso o sebetsang.(℃) | 1200 | 1400 | 1300 | 1400 | 1650 | |

| Axial crushing matla (MPa) | Omme | ≥11 | ≥20 | ≥11 | ≥22 | ≥25 |

| Ho qoelisoa metsing | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | |