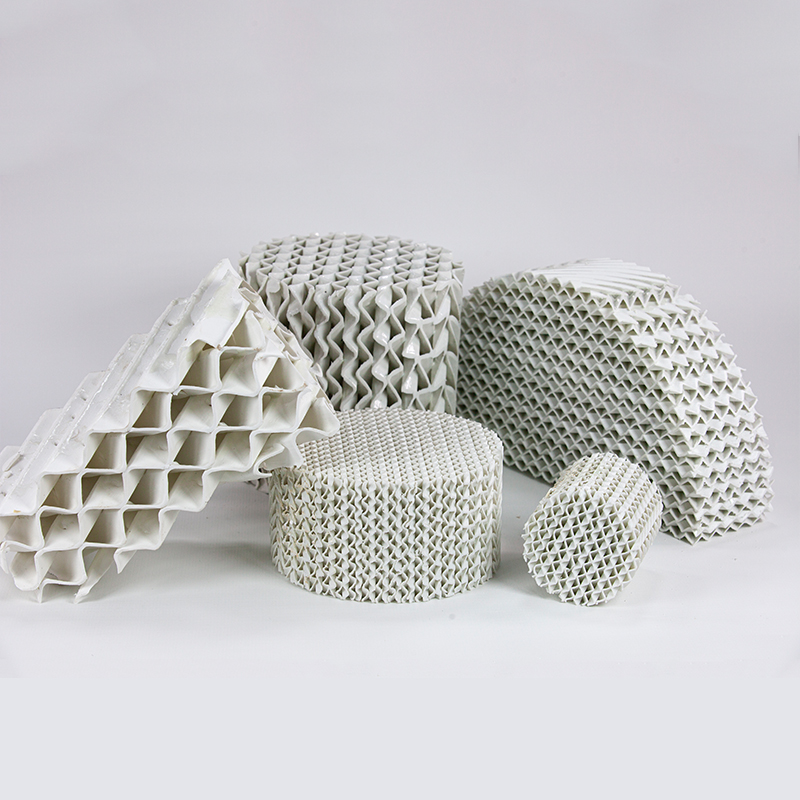

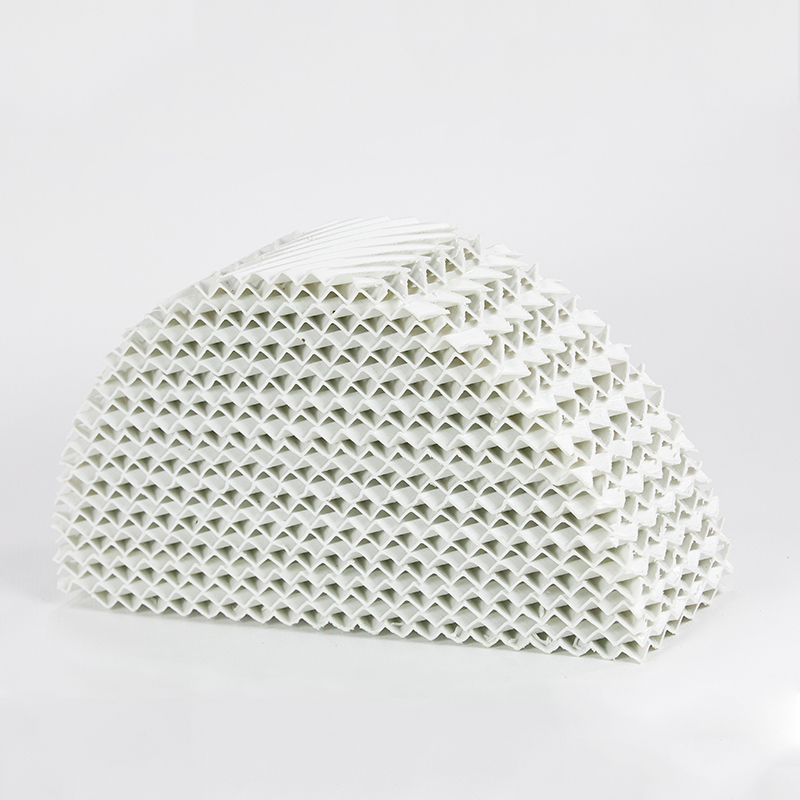

Ceramic Structured Packing e nang le mofuta oa 125Y & 250Y

Ka lebaka la sebopeho se ikhethang sa ceramic, ts'ebetso e ntle ea hydrophilic, bokaholimo ba eona bo ka etsa filimi e tšesaane haholo ea mokelikeli oa moferefere o sekamang le likanale tse tortuous li ka khothaletsa moea empa li sa emise ho ts'oana le moea oa tšepe oa tšepe o ka etsa hore pack ea ceramic, 'me e hanyetsane le kutu, ts'ebetso e hanyetsanang le mocheso o phahameng oa mochini oa tšepe e ke keng ea bapisoa. overheating, aggregation, and coking.Sehlahisoa sena se entsoe ka boleng bo phahameng ba lik'hemik'hale tsa letsopa tsa letsopa tse entsoeng ka lihlahisoa tse tala 'me li fetoha, tse hanyetsanang le mocheso o phahameng le khatello e phahameng, botsitso bo botle ba lik'hemik'hale le matla a phahameng, ke sejari se loketseng ho tšehetsa mefuta e sa tšoaneng ea li-catalysts.

Tlhahlobo ea Lik'hemik'hale

| Sebopeho | Boleng |

| SiO2 | ≥72% |

| Fe2O3 | ≤0.5% |

| CaO | ≤1.0% |

| Al2O3 | ≥23% |

| MgO | ≤1.0% |

| Tse ding | 2% |

Thepa ea 'Mele

| Index | Boleng |

| Matla a khoheli (g/cm3) | 2.5 |

| Ho monya metsi (wt%) | ≤0.5 |

| Ho hanyetsa asiti (wt%) | ≥99.5 |

| Tahlehelo ea ho cha (wt%) | ≤5.0 |

| Max. Mocheso oa ho sebetsa.(℃) | 800 |

| Matla a silakanya (Mpa) | ≥130 |

| Boima ba Moh(Sekala) | ≥7 |

Letsatsi la Tekheniki

| Spec. | Sebaka se ikhethileng (m2/m3) | Boima ba bongata (kg/m3) | Void ratio (%) | Obl. Lenaka | Ho theoha ha khatello (mm Hg/m) | Theo. Letlapa (m-1) | Bophara ba Hydraulic (mm) | Mojaro oa metsi (m3/m2h) | Max. Factor m/s (Kg/m3)-1 |

| 125Y | 125 | 320 | 90 | 45 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 250Y | 250 | 420 | 80 | 45 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 450Y | 450 | 520 | 72 | 45 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45 | 6 | 7 | 5 | 0.15-100 | 1.3 |